Our Machinery

Metallurgical Laboratory

Analog Rockwell Hardness Tester

Analog Rockwell Hardness Tester Digital Rockwell Hardness Tester

Digital Rockwell Hardness Tester Leeb Portable Hardness Tester

Leeb Portable Hardness Tester Stereo Zoom Microscope

Stereo Zoom Microscope Inverted Metallurgical Microscope

Inverted Metallurgical Microscope Granite Surface Plate

Granite Surface PlateThe metallurgical testing services at Pyrotherm Technologies are performed in accordance with ASTM and other industry specifications. Detailed internal procedures are also observed to ensure efficient order processing and the reliability of test results. Customers receive a Certified Test Report showing the complete results of each metallography test.

The first step in metallurgical analysis is sample preparation. Samples are prepared in our metallurgical lab using abrasive cutting, mounting, grinding and fine polishing techniques, as well as etching when required. The metallurgists perform various types of microstructure and macrostructure examinations and hardness testing. They can evaluate defects, determine structural features, evaluate the effects of heat treatments, and ensure materials conform to required specifications.

The first step in metallurgical analysis is sample preparation. Samples are prepared in our metallurgical lab using abrasive cutting, mounting, grinding and fine polishing techniques, as well as etching when required. The metallurgists perform various types of microstructure and macrostructure examinations and hardness testing. They can evaluate defects, determine structural features, evaluate the effects of heat treatments, and ensure materials conform to required specifications.

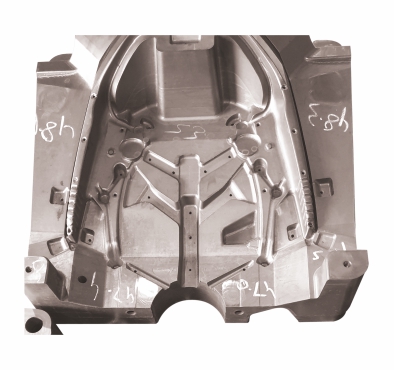

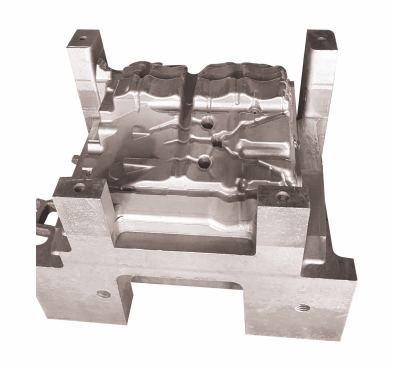

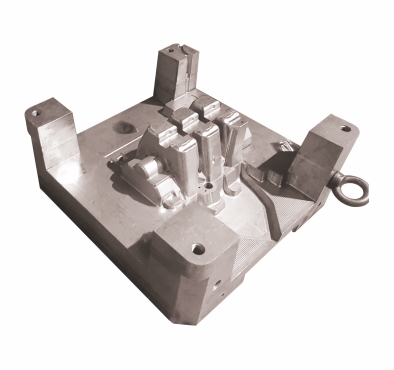

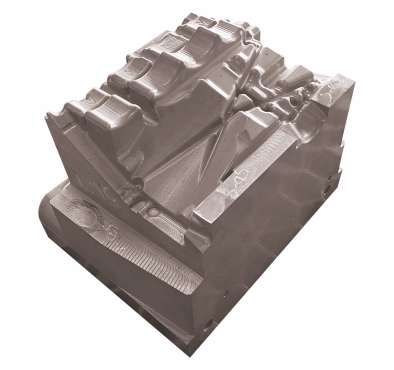

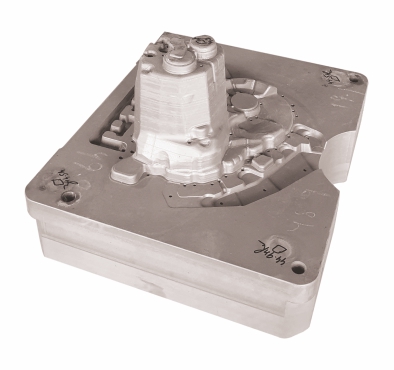

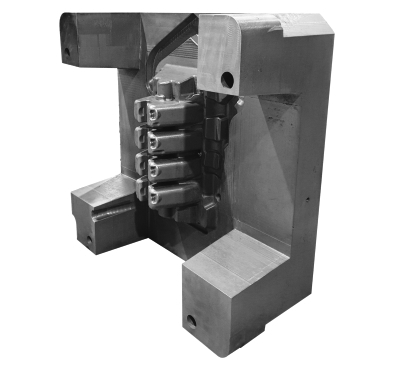

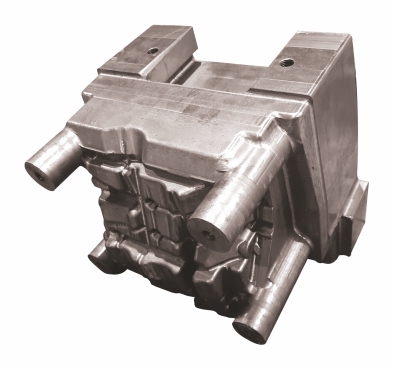

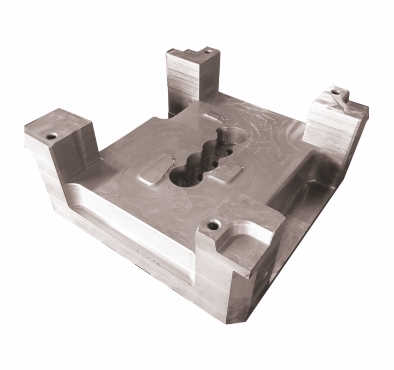

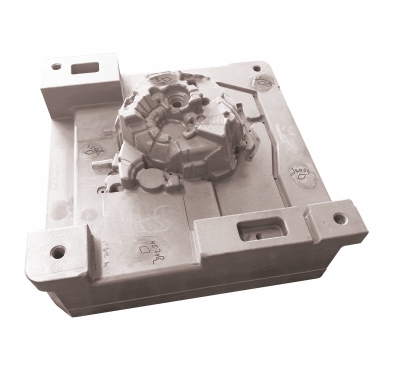

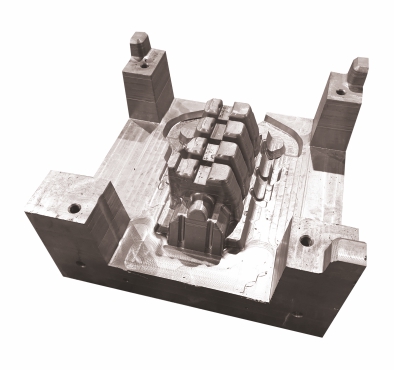

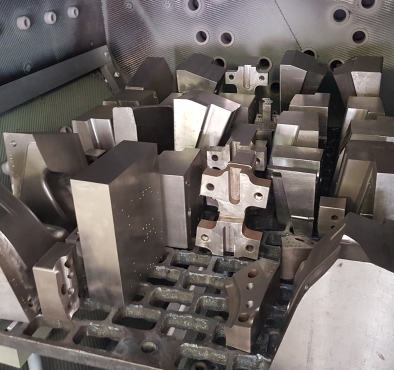

JOBS HEAT TREATED AT OUR FACILITY

Steel Grades Processed

| Category | Grades |

|---|---|

| Hot Worked Steel | SKD-61, DAC, HDS, H11, H13, 1.2344, DH31-EX, DHA |

| Cold Worked Steel | SKD-11, D2, D3, D6, 1.2379, |

| High Speed Steel | M2, M3, M4, M34, M35, M36, M42, M45, S290, S390, T1, T2, T15, ASP 23, ASP30, ASP60 |

| Austenitic Stainless Steel | SS304L, SS316L, SS301, SS303, EMS247 |

| Martensitic Stainless Steel | SS310, 1.2083, M310, M390 |