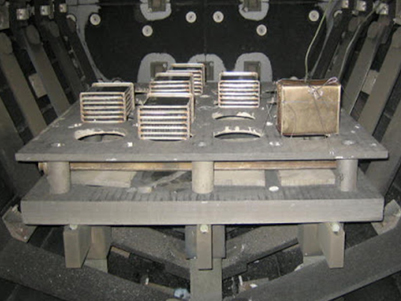

PYROTHERM TECHNOLOGIES operates in compliance with the latest quality standards using state of the art machinery supervised by a team of qualified and experienced specialists. We can process all the popular air hardenable Hot Work Tool Steels, Cold Work Tool Steels and High-Speed Tool Steels. The company is equipped with five Vacuum furnaces, three Atmospheric furnaces, one Sub-zero chamber and one Nitriding furnace. The company is rapidly expanding its capacity and capability through addition of more machines. Due to sufficient number of furnaces a turn around period of three to four days is easily achievable.

Environmentally safe

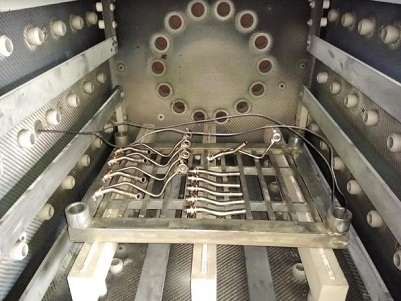

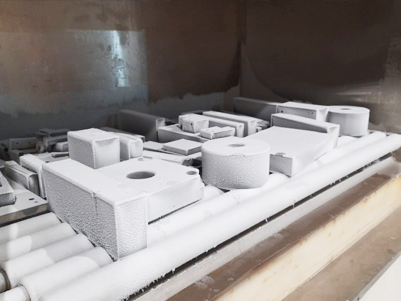

The principal reasons for the use of vacuum processing techniques is to prevent surface contamination of the metal from oxygen and other potential contaminant gases. In addition low pressure operating conditions will reduce the risk of surface contamination to a level which is below the materials oxidation level.

Advantages of Thermal Processing of Metals by Vacuum Heat Treatment

• Zero toxic protective gases containing CO with no CO2 emission

• Use of inert gases

• Zero health hazards in the work shop

• Zero danger of explosion or open flames .

The process of vacuum heat treatment is a means of treating Complex pieces of metal while also conferring additiona benefits such as strength and cleanliness to the metal it is treating in an environmentally friendly process with no harmful side effects.

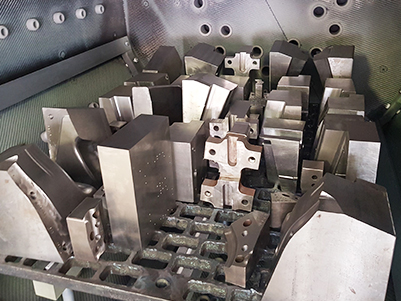

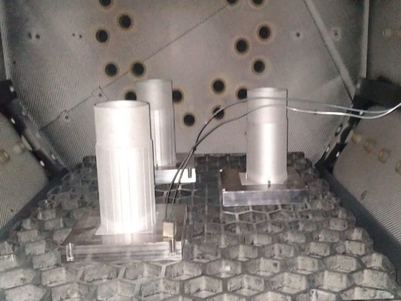

Metal parts that require vacuum heat treatment are parts that must withstand high heat and stress in actual operation. These are difficult parts to form in the first place and may take several forming operations to achieve the final part. The benefit of vacuum heat treatment is that it can take a part which needs further forming and soften the part so that it is ready for more.

These materials also respond well to the controlled environment of the treatment process. Parts emerge from heat treatment without scaling or discoloration and require no further cleaning, polishing or washing procedures before the next operation.